From heat to chills: why you need a coolant temperature sensor and how to check it

The coolant temperature sensor itself (DTOZH) is a simple and very reliable thing. But the failure of this sensor can greatly complicate life, since it affects many engine parameters. You can search for a long time for the cause of a difficult engine start or his desire to stop at a hot one, or you can hide it in a small detail, which is not very expensive, but simply changes with your hands. But how to understand that it's time to replace it, or at least check?

Starting, warming up and overheating

What is DTOZH from the point of view of physics? It's just a thermistor, a resistor (resistance) whose parameters depend on temperature. More precisely, there is only one parameter – the resistance itself. The higher the temperature of the coolant, the lower the resistance (inverse relationship). To measure this resistance, a constant positive voltage of 5 volts is applied through one of the wires in the sensor connector. So everything is simple: by how much the voltage has dropped, the resistance of the thermistor is measured at the current time, and the data is sent to the ECU for processing. And he recalculates what the temperature of the coolant is. Why do you need it? And it is necessary to solve various problems.

First, properly prepare the fuel-air mixture. With a cold start, it should be richer, which means it needs to end. Secondly, the throttle must be opened properly in order to properly start a cold engine and, as it warms up, reduce the speed of the crankshaft. Thirdly, when the car is already warm, it is necessary to check the temperature of the antifreeze and, if necessary, turn on the cooling fan. All this is provided by the temperature sensor even in simple machines.

In more complex machines (and engines), the sensor can perform other functions as well. Its information helps control the electronically controlled thermostat, and if there are two sensors (on the outlet pipe of the unit and on the pipe at the outlet of the radiator), they check the operation of the cooling system. They can change the speed of rotation of the fans, they can signal that something is wrong and the cooling system is not working.

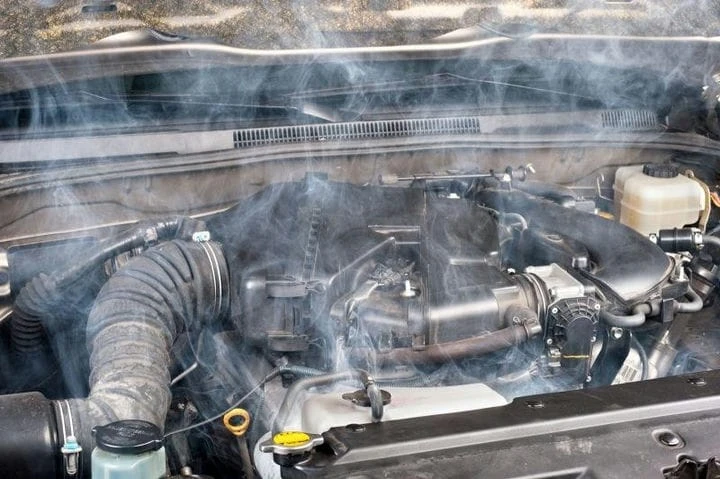

In general, DTOZH has many functions. And if it suddenly stops working, the engine will behave incorrectly. First, a cold start can be very difficult. The throttle may not open to the desired angle, which will cause insufficient speed after starting the engine. And when the temperature rises, the opposite situation may occur: despite the increase in temperature, the speed will not decrease, in addition, the cooling system fan may not turn on, and mixing errors may appear. Symptoms vary, and the check engine icon can be dangerously quiet. And if it lights up, then by itself it will not say anything – you will need a diagnostic scanner.

Well, everything is simple with him – just check for errors in the range P0115 – P0118 or, even better, check the values u200bu200bthat the sensor produces when the antifreeze is heated. In a word, life with a scanner is simple and beautiful, and the best and easiest way to check the DTOZH is to check the diagnostic connector with a decent scanner. But what if it's not available?

I'm not guilty!

Unfortunately, you need at least a multimeter. But sometimes you can do without it simply due to the simplicity of the sensor design.

Really, what could go wrong? Almost nothing. Unless, of course, tap water is poured into the cooling system, the resistance itself could rot (after all, the sensor is in antifreeze, the temperature of which it measures). In other cases, its wiring fails. Therefore, checking the sensor should begin with checking the wiring. First, remove the connector chip and see if everything is in order there. If we see disgusting green (or gray, or even white) oxides, then we first need to clean everything and only then carry out diagnostics.

It makes sense to slightly pull on all the wires suitable for the sensor. It is likely that one of them has rotted inside the insulation and is not doing its job. This is much more likely to damage the sensor itself.

If the contacts are clean and the connector wires are not rotten, you will need a multimeter. First, we check whether a constant voltage is supplied to the sensor. If it is and is really constant (as I said above, it is usually five volts), you can check the sensor itself. There are two ways to try it: for the lazy and for the boring. First, let's try to do it for the lazy.

You don't need to remove the sensor. You just need to measure its resistance. But it is advisable to do this at least three times: when the engine is fully warmed up, 20 minutes after it is turned off and after the engine has completely cooled down. And now we look at our three dimensions. Since the resistance of the thermistor varies greatly with temperature (from 150-200 ohms on a hot engine to 7-8 kOhm to zero), the difference in measurements should be very significant. If this does not happen, then something is clearly wrong with the sensor. You can safely buy a new one and not suffer from additional measurements. It was the way of the lazy.

The path of boredom is, of course, more difficult. I don't know how many times they walk in life, but it exists. The first step along the way is to remove the sensor itself. To do this, you need to drain a lot of antifreeze and not get burned. The sensor is threaded so you just need to unscrew it.

We take it home and prepare something like a jug of water and a thermometer. Then you probably already understood everything: we measure the resistance of a sensor immersed in water with a certain step (3, 5 or 10 degrees, depending on the degree of perforation). As a result of the actions, we get the resistance curve and see if everything is in order on it. Of course, to find out, you need to find data on the sensor you are testing. If the resistance values at a certain water temperature correspond to those indicated in the reference book, then everything is in order.

Why did I call this particular method boring? Because, in principle, it is enough to take two measurements – at a known room temperature and in boiling water (which is always about 100 degrees) – and compare them with normal values. Thermistor is good or not. Theoretically, it can even lie, but this is a very rare case.

Instead of a conclusion

There is no way to extend the life of the coolant sensor. As I said, its wiring and connector, which are in an aggressive environment, suffer more often. Their lives are spoiled not only by street dirt, but also by the fact that they work in very hot antifreeze. There is no escape from this, so here you can remember only one rule: before you rush to the store for a new DTOZH, you need to check its wiring. Basically, this rule works with almost any sensor. In addition to more capricious ones, for example, parking sensors can be killed with a high-pressure washer.

But what really hurts the sensor is a very old antifreeze in the form of a brown slurry, poured into the cooling system. When this junkyard overheats, it becomes even more aggressive, and even a device as simple as this sensor dies easily inside. Therefore, at least occasionally it is necessary to change the antifreeze: with a large amount of water, rust and dirt, it cools down worse and reduces the life of other parts (and I'm not talking about the sensor, but, for example, on radiators and a pump).

Well, the easiest way to manage DTOZH is still a scanner. Yes, you can do without it, but with it you can do everything faster. When working with a multimeter on a hot engine, take care of your hands and remember that the first time after the engine is stopped, the pressure in the system is still higher, so before removing the sensor, you must carefully drain the antifreeze (in any case, if necessary.