Wrong material, thickness and more: why the wires for “lighting up” cannot start the engine

Many car owners, despite the proliferation of pocket starter “boosters”, still consider “lighting” cables to be the most reliable way to start an engine with a dead battery, which are reliable due to extreme space, are not afraid of temperature changes, humidity, drops and shocks. However, even the highest quality cables at first glance can be ineffective. Why is this happening, how do you pre-determine the “pod”, and why is a match needed when choosing leads in a store?

We were prompted to talk about this topic by the stories of two colleagues who actually found the starting topics ineffective. One inherited the cables from the previous owner by buying a used car, and the second bought his own from the supermarket, choosing far from the cheapest. However, several use cases, where the engine of a car with a stubbornly discharged battery did not want to start, just sobbed sadly and burned out the starter relay, both suggested that something was clearly going wrong.

Upon closer examination, it became clear why we decided to tell our readers about the nuances of how to make things so, at first glance, simple, like two thick threads with “crocodiles” at the ends. Also, with the onset of cold weather, many turn to car dealerships for this accessory, and the demand for them is growing rapidly.

Anyone who remembers school physics and knows how to repair an outlet at home knows that the thicker the wire, the more current it can flow through itself. Yes, a large current can also flow through a thin wire, but not for long. The voltage drop across the wire will be too great, and thermal heating will quickly melt first the insulation and then the metal of the conductor itself. For this reason, “lighting” cables have the same cross section (more or less) as standard automotive patch cables. Everyone who is familiar with electrical engineering at the household level has probably seen the table of correspondence between the cross section and operating currents. If we take values close to the starting powers from there, we will see that: – for a current of 200 amperes, a wire cross section of about 70 square millimeters is required;

– for a current of 250 amperes, a wire with a cross section of about 90 square millimeters is required;

– for a current of 300 amperes, a wire with a cross section of about 120 square millimeters is required.

Flexible wires consist of single cylindrical conductors, and the total cross section is determined by calculating the cross section of a single wire by measuring its diameter and calculating it using the well-known formula S = πr2, after which the result is multiplied by the number of conductors. In principle, it is possible, without much loss of accuracy, to simplify the process and calculate the cross section by simultaneously measuring the diameter of the entire “package” of wires. For our purposes this is sufficient.

The problem is that the owner of a rare car pays attention to this parameter, especially since the manufacturers of light cables do not advertise it. The buyer indirectly looks at the cross section of the wire, based on its outer thickness along the diameter of the insulation. And he evaluates his flexibility separately, because he knows how plastic is prone to sunbathing in cold and even frosty conditions. Sometimes the insulation of wires in the cold becomes so rigid that it is impossible to even stretch them from car to car – as soon as the wires are taken out of hand, they tend to shrink into a loop, where they were twisted and torn during storage. “crocodiles” from the battery terminals! Therefore, if the thread is visually thick and elastic, it is considered suitable and commercial …

However, the problem is that only plastic scabbards can be thick – and sometimes there is natural Chinese hillbilly inside. This happened to one of our colleagues, who, having learned the cause of the failures, gave us the wires for experiments, allowing us to simply dispose of them after the search.

The outer diameter of the wire for insulation is 7.5-8 millimeters. Not too thick, but generally tolerable. In fact, almost the entire array was flooded with an unpleasant smell of plastic, in the thickness of which a thin copper bundle was hidden, the total diameter of which did not even reach 2 millimeters! Thinner matches! Recalculation of the section gave us an operating current of about 20 amperes, although in fact the starter wires must withstand at least 200 amperes.

That's why those wires just didn't work. The voltage drop on them turned out to be so large that the current from the donor battery simply did not reach the recipient battery in the right amount …

But if in the first case the threads were not only cheap in essence, but also looked the same, then in the second they looked outwardly of very, very high quality. Powerful crocodiles in a plastic case, thick cables in a colored sheath, which retained their elasticity very well in the cold – this, at first glance, is a solid thing. However, they still performed poorly, and several use cases, with varying degrees of success, made the owner less confident in their reliability.

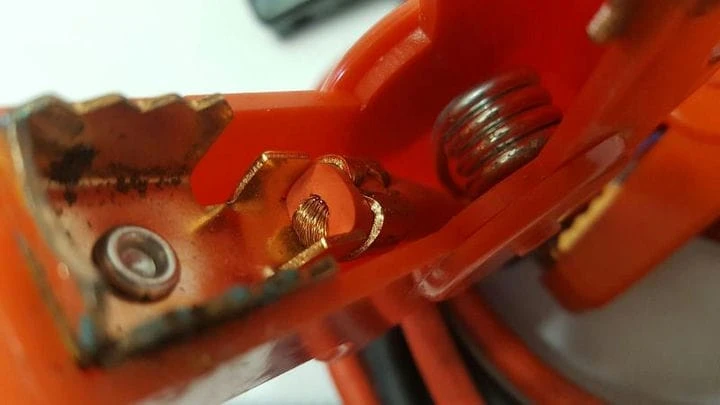

The cause of the breakdown was also found without difficulty! Firstly, despite the high quality and thick insulation, the copper strands inside do not stand up to criticism – again, they are as thick as a match or not much thicker. And secondly, these wires use an extremely unsuccessful method of terminating the cores on the “crocodile” terminals. A bundle of copper conductors is not corrugated directly into the metal, rigidly, but wound on an insulator and crimped together with it. As a result, the contact is not rigid, but through a rubber-plastic layer, which eventually loses its elasticity, and the fastening of the wire to the metal of the terminal is weakened.

In order not to make a mistake when buying leashes, we will give some important tips.

- The first, as is already clear, concerns the working section of the wire and its ability to transmit large currents without sagging and overheating. Before buying, you should see where the cable ended. There you will see a bare area, which will allow you to evaluate its cross section. It is unlikely that it will be possible to technically measure the thickness with a caliper and calculate “two pi-er-squares” – there, as a rule, one cannot crawl with a measuring tool. But you can use a normal match as an approximate reference. Its thickness is about 2 millimeters, respectively, the cross-sectional area is 4 square millimeters. A copper wire of this section is designed for a current of about 30 amperes, so the total cross section of the starting wire should be at least three times the thickness of the match, and at least 5-6 times over the field. If a bundle of copper wires is comparable to a match, then you can't get these cables for free! With their help, you can only reliably start a moped.

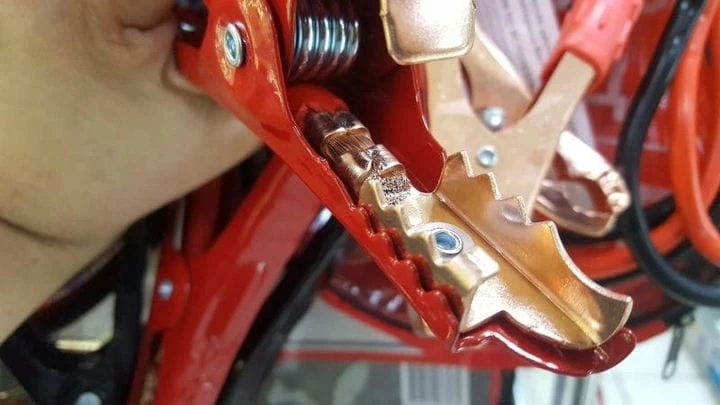

- The second tip concerns the quality of embedding the wire with crocodile metal. Avoid the aforementioned fraudulent blocking with a plastic insulator! The pressure must be tough, “without intermediaries.” Or, as an alternative and equivalent option, welding. The method of terminating the cable is determined simultaneously with the study of its cross section: for this, it is necessary to remove the rubber insulating cover from the “crocodile” or fully open its claws. Manufacturers of high-quality wire, among other things, connect the upper and lower jaws of each “crocodile” with a thinner piece of wire to increase the contact area with the battery terminal and reduce current losses. This is optional, but highly recommended.

- The third tip concerns the material of the crocodile skin sponges. In cheaper versions, it is bare steel or galvanized steel with a thin layer of copper. Both of these options are few and easily detected with a magnet. Steel provides extra durability, reinforced by rust, and the thin layer of copper wears off quickly. The correct option is pure copper. Either the whole “crocodile” is made of it, or (which is quite acceptable and no worse) only its contact part, toothy.