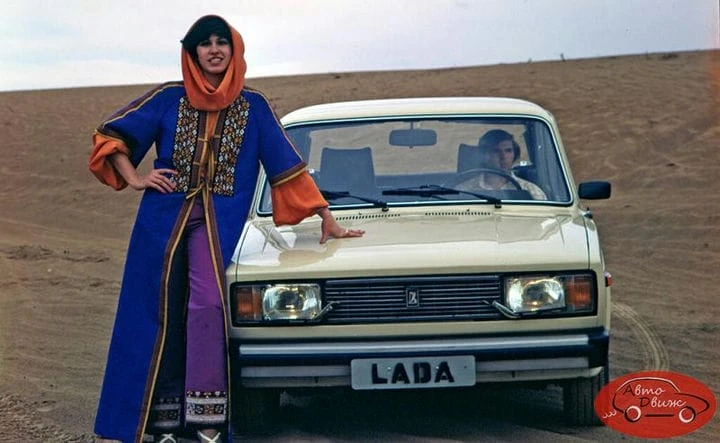

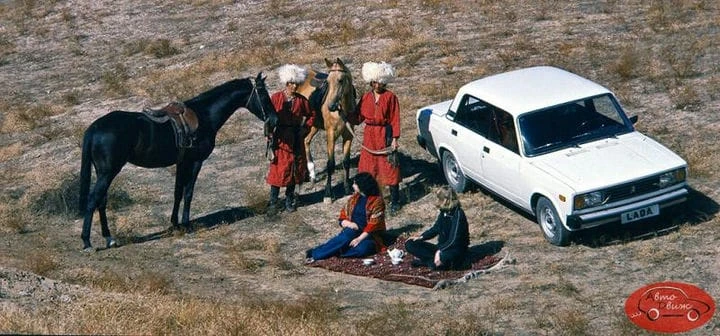

VAZ-2105 in the photos of “Autoexport”

By August 1976, at the Volga Automobile Plant, a technical assignment was drawn up, in which all the necessary changes for a promising car designed to replace the “one” were written down point by point. 3.5 years after the approval of this document, full-scale serial production of the new VAZ-2105 car will begin in Togliatti.

The task of designing the Zhiguli five was clearly set: the car should not look like a continuation of the old base family, but the beginning of a new one, finally losing its resemblance to the VAZ-2101. Perhaps the most difficult part of the work on creating a promising car went to the Style Center. The difficulty lay primarily in the fact that, in fact, the body of the five had to remain old: work on external forms should not have led to a change in established welding processes. The frame, floor and roof were not allowed to be touched by the designers. As a result, the VAZ-2105 received an original appearance by replacing mainly only external body panels.

If in external forms it was necessary to adhere to the “old course”, then inside the car was completely updated: a new instrument panel, on which a completely different combination flaunted, a new steering wheel and seats with height-adjustable head restraints, new molded door and ceiling upholstery, unusual to look at Soviet motorist. Only the levers-sliders for controlling the heating and ventilation system of the cabin and the notorious stove tap, which spoiled the nerves of three more generations of owners, remained old.

Another innovation of the VAZ-2105 was completely original headlights: for the first time in the practice of the Soviet automotive industry, low and high beams, side lights and direction indicators were combined in one housing. In addition, it was possible to adjust the direction of the light beam using a corrector licensed in France.

The pivoting window in the front doors was removed – in addition to reducing the noise level, this also led to an increase in passive safety, which was required by new industry standards and the latest UNECE regulations. In the future, to strengthen the rigidity of the structure during a side impact, the door frames provided for the installation of safety bars. And to mitigate the consequences of a collision, the bumpers could be fixed with the help of hydraulic buffers (however, the serial “five” for the domestic market did not wait for this).

But the engine for the fifth model was decided to put the old one – VAZ-21011, but with a caveat: in order to comply with foreign standards in terms of noise and toxicity, it had to be modernized. As a result, there have been many improvements. Firstly, a new Ozone carburetor appeared on the VAZ-2105, which made the car more economical. The second innovation was a toothed camshaft drive belt instead of a chain. To top it off, a new oil sump and a cast aluminum cylinder head cover were used. The motor modified in this way was assigned a new index to match the car – VAZ-2105. Finally, to further improve efficiency and reduce noise levels, the designers “played” with the transmission ratios.

Few numbers. In August 1979, three experimental VAZ-2105 vehicles were successfully tested for compliance with international requirements in France. In January 1980, AvtoVAZ launched the serial production of the “five”, and 9 months later the first batches of the VAZ-2105 were received by Finland, Norway, Sweden and other countries. Mass export of “fives” abroad began in December 1981.

In our country, the “five” also enjoyed love. But if at first the VAZ-2105 was valued for its “luxury” and dissimilarity to previous models of VAZ cars, then in the 2000s, the main advantage of the “five” was cheapness. It was the most affordable new car on the market among the “normal” ones: only Oka, Tavria Nova and Slavuta were cheaper than it, which many consumers even then considered “under-cars”. Serial production of the VAZ-2105 ended in December 2010, and their total circulation slightly exceeded the mark of 2 million copies.